Our engineering team works together with you to understand your specific needs and develop tailored electric final drive solutions. Through the use of our DriveSys© software, we can also calculate optimal torque, output speed and temperature curve.

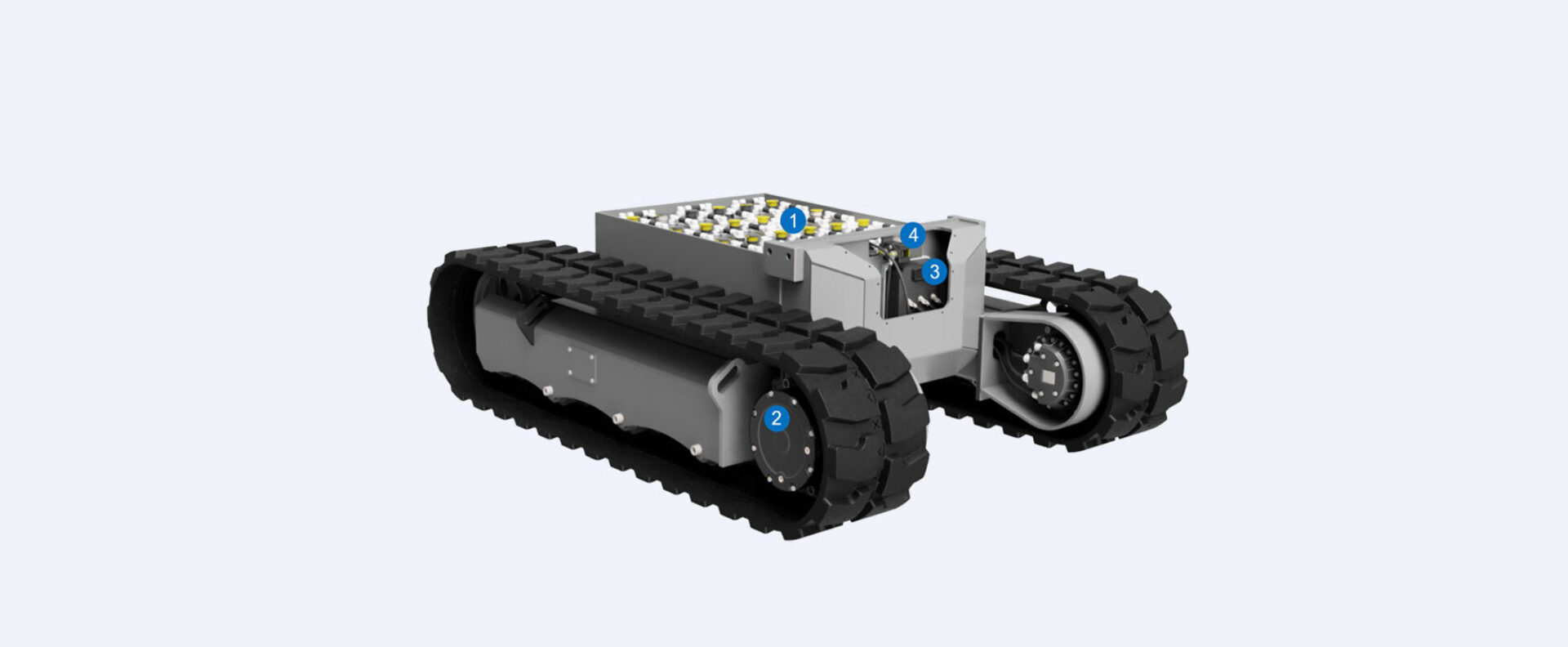

1 - BATTERY

The decision to use lithium or lead acid batteries depends on the specific needs of your system. Weight, cost, capacity, efficiency and lifespan are important attributes to consider between battery options.

2 - ELECTRIC FINAL DRIVE

I&W offers a range of high-performing electric final drives that use innovative, patent-pending technology. Our high precision planetary gearbox delivers output speed to meet various needs.

3 - CONTROLLER / INVERTER

The controller coordinates the performance of an electric final drive, which makes it an important component of the system. The inverter meanwhile changes direct currents to alternating currents for the Permanent Magnet Synchronous Motor (PMSM).

4 - RELAYS

In most applications, relays provide safety measures through switches that consist of input terminals. They can make contacts, break contacts or both in order to safeguard the safety of the machine.

Tailored Engineering Solutions

Installation and Set-up

I&W engineers will help you during your installation and set-up phase, ensuring the seamless integration of your new electric drive system.

Pre and Post Sales Service

We provide professional and efficient service, whether pre or post sales. We are easily reachable by phone and e-mail with real people behind every interaction with you.

Product Performance Test

All our drives undergo a performance test before leaving the factory. Test report is provided for easy tracking. If you choose complete system solution, I&W will set-up drive and controller with factory settings according your requirements. It will help you to reduce your preparation and implementation time on spot.